Abstract:

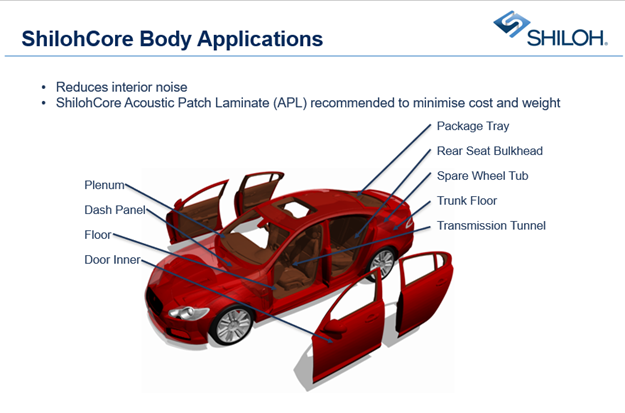

Shiloh Industries is a global innovative solutions provider focusing on light weighting technologies that provide environmental and safety benefits to the mobility market. One of Shiloh’s key products is ShilohCore, a formable laminate product (metal-polymer-metal) that uses proprietary viscoelastic material to provide vibration and acoustic damping for noise, vibration, and harshness (NVH) applications in the automotive industry.

Students in this team will design and develop a viscoelastic adhesive formulation that:

- provides sufficient adhesion to metal substrates, mainly steel,

- is thermally stable up to 200C for 1 hour, and

- results in a high damping laminate material (Tan delta > 0.3).

They will utilize a detailed understanding of crosslinking mechanisms to select potential formulations. Ideally, they will be able to adjust the glass transition (Tg) of the formulation to targeted temperatures. Students will characterize their formulation using Differential Scanning Calorimetry (DSC), Dynamic Mechanical Analysis (DMA) and Thermal Gravimetric Analysis (TGA) to identify cure profile, damping temperatures and thermal stability of the material.

Impact:

Development of high damping formulation would enable Shiloh to expand the product portfolio which would help in increasing sales and profitability. Understanding key design parameters and establishing tolerance limits would decrease product variability, increasing efficiency and maximizing profits. Students will acquire a deeper understanding of NVH damping applications in the automotive industry and will also enable them to develop their skills in research and development arena.

Polymer Science (2-3 students)

Specific Skills: Polymerization theory and practical experimental technique.

Likely Majors: ChE, MSE, CHEM

Application Process Development (1-2 students)

Specific Skills: Fluid dynamics associated with adhesive delivery.

Likely Majors: ChE, MSE, ME

Analytical and Physical Properties Testing (2 students)

Specific Skills: Analytical and physical properties testing.

Experience with Differential Scanning Calorimetry (DSC), Dynamic Mechanical Analyzer Testing (DMA), TGA a plus.

Likely Majors: CHEM, MSE

Statistical Evaluation (1 student)

Specific Skills: Design of Experiments, data interpretation, categorization. This student will also participate in the experimental laboratory work.

Likely Majors: ChE, MSE, or CHEM – all with double major/minor in either IOE or STATS

Sponsor Mentor

Varun Kalur

Varun Kalur

Product Engineer – Specialty Metal Products & Stampings

Varun has worked at Shiloh Industries for 4 years, starting as an R&D Engineering Technologist. He currently leads the development of viscoelastic materials for NVH damping applications and responsible for production scale-up operations. Prior to his work at Shiloh, Varun worked as a research engineer to develop high performance polymers for aerospace and defense applications. He has a graduate degree in Chemical Engineering from Cleveland State University.

Executive Mentor

Steve Lin

Steve Lin

Steve is the Executive Director of Engineering & Technology for Shiloh Industries, a leading global full-service supplier of light weighting, noise & vibration and material joining/processing solutions to the automotive, commercial vehicle and industrial segments. With over 30 years of experience in automotive engineering.

Steve possesses a unique combination of product development, quality control and manufacture process experience, most recently in Hot Stamping, Laser Welding, CMT Welding, FS Welding, structure adhesive joining, High Pressure Die Casting and light weighting applications. During his career, Steve has held lead process development position at Tower Automotive, product design and development positions at Ford Motor Company, Visteon, Delphi, Sodecia and Executive Director of Advance Engineering position at Metalsa before working at Shiloh Industries.

Steve holds several patents for Chassis product design, car seat design, assembly process and material joining. Steve received his Bachelor of Science from North China University of Technology and Master of Science degrees from the University of Detroit Mercy.

Faculty Mentor

Brian Love

Brian Love

Professor, Materials Science & Engineering

Professor Love’s functional polymer materials laboratory is focused on several themes. He has his BS in Chemistry and MS in Metallurgical Engineering (Polymers) from the University of Illinois, and his PhD in Applied Science (Material Science) from Southern Methodist University.

Citizenship Requirements:

- This project is open to all students.

- International students on an F-1 will be required to declare part-time CPT during Winter 2023 and Fall 2023 terms.

IP/NDA: Students will sign standard University of Michigan IP/NDA documents.

Internship/Summer Project Activities: No summer activity will take place on the project.