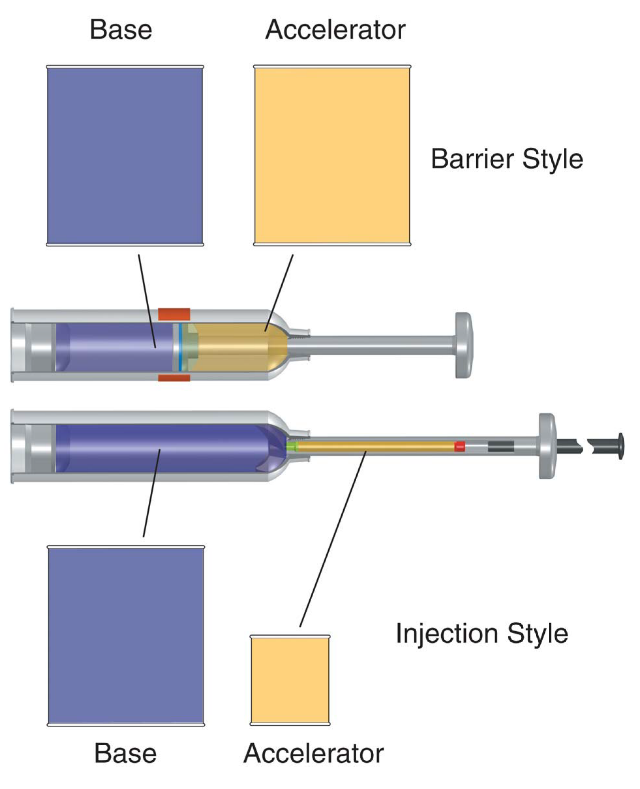

Single use plastic cartridges and mixing rods for adhesives and sealants are convenient and popular, but they are not environmentally friendly. Students on the PPG team will bring their creative ideas and generate a very wide range of packaging containment, mixing, and delivery concepts and produce conceptual demonstrations and feasibility evaluation for the most promising concepts.

Abstract:

PPG is a global team of more than 50,000 innovators, with a vision to be the first-choice partner to meet their customers’ evolving needs for innovative paints, coatings, and specialty materials. One of their product lines is Semkit®, a ready-to-use disposable cartridge-based system for storing, mixing, and application of numerous adhesives and sealants. PPG supplies over 10 million of these disposable cartridges each year. While they are convenient and easy to use, they are not currently reusable or easily recyclable. To support PPG’s corporate target to have 50% of their sales from sustainable advantaged products by 2030, students on the PPG team will ideate, down select, and demonstrate a more sustainable method for containment, mixing, and delivering these adhesives.

Impact:

With a growing focus on sustainable operations, many companies are exploring alternatives to single use plastic containment. Furthermore, innovative dispensing methods that allow all or significantly more of a product to be dispensed may allow containers to be more easily recycled and cut down on chemical waste. By either reducing the amount of non-recyclable plastic or eliminating it all together, PPG’s environmental footprint stands to improve substantially.

Scope:

Minimum Viable Product Deliverable (Minimum level of success)

- Literature review of PPG best practice design, previous data/project work, and understanding of consumer needs, including patent search and review of competitors’ product offerings

- Awareness and dissemination of existing approaches to sustainable containment, mixing and dispensing

- Development of customer and consumer requirements

- Leverage the multidisciplinary background of the team to development of a multitude of design ideas (50+) to address key recyclability and reusability concerns

- Perform full feasibility studies on top 10 designs for environmental impact and performance against consumer requirements

- Utilize creative fast prototyping methods to demonstrate a short list of concepts (e.g., 3D printing, surrogate materials, simulations, etc.)

- Select the top design ideas with input from the team’s mentors

- Produce a prototype design for 2 or 3 of the top priority concepts

Expected Final Deliverable (Expected level of success)

- Functional prototypes that address top requirements

- Student evaluation of the design against the status quo for both performance and environmental impact

- User group testing with end users or PPG surrogate employees

Stretch Goal Opportunities: (High level of success)

- Include an element of circularity into the solution (circular economy). Extra kudos for identifying a PPG specific waste stream that could be incorporated

- Blind focus group comparing a functional prototype to existing technology(ies) to observe and measure impact on the pain points of the current design

- Along with PPG mentor(s), apply for a patent application for a sustainably advantaged dispensing, mixing, and containing system

- Develop a system with near full transfer efficiency so that IF single use plastics are used, they can be recycled

- Propose an entire system or approach to circularity within this segment considering the proposed packaging solution (might look to companies like Keurig or Nespresso for inspiration)

Creative Product Design (2 Students)

Specific Skills: Creative design concept skills, interest in product design, combined with practical fabrication skills in any medium

Likely Majors: Any Physical Science/Engineering

Mechanical Design and Prototyping (2-3 Students)

Specific Skills: Design concept generation, determining user needs and techniques for fast prototyping, mechanical structures and evaluation techniques.

Likely Majors: ME, NAME, NERS

Sustainable Product Design (2 Students)

Specific Skills: Designing for recyclability and reusability, environmental analysis including life cycle analysis.

Completion of MSE 481 or ME 577 is a plus

Likely Majors: MSE, ME, CEE, EHS, SEAS

Polymer Material Properties (1-2 Students)

Specific Skills: Knowledge of material properties and physical evaluation techniques, particularly plastics and adhesives, selection of polymers, fillers, etc. to help ensure performance properties can be met

Likely Majors: MSE, ChE, Chem

Additional Desired Skills/Knowledge/Experience

Strong candidates will have familiarity or experience with some of the following items, and a positive attitude to learn what is necessary, as the project gets underway.

- Practical fabrication skills, including 3D printing, injection molding, simulations

- Polymer and composite properties and mechanical testing

- Modeling of mixing and/or modeling of dispensing to help focus design principles

- Knowledge of shear effects on Newtonian and Non-Newtonian fluids

- Basic understanding of chemical reactions, and ability to apply knowledge in this area to impact of mixing ratios in single or multicomponent systems

- Interest in product design and product development

- Minor in entrepreneurship is a plus

- Experience / interest in environmental evaluation of products

Sponsor Mentor

Justin Martin

As director of applied research, Justin currently leads the Aerospace Materials and Land Based Defense R&D team at PPG’s Coatings Innovation Center located in Allison Park PA. He is a scientist and leader with a sustained record of innovation with 10 issued patents and more than 12 pending. Justin has cross-functional interests with individual and team accomplishments spanning nanotechnology, composites, coatings, corrosion science, biomaterials, surface science, polymer science, sealants, characterization and medical devices. He holds a Ph.D. in inorganic chemistry from Binghamton University.

Faculty Mentor

Professor Steve Yalisove

Materials Science & Engineering

Professor Yalisove’s current research focuses on understanding the relationships between atomic structure and materials properties at surfaces and interfaces in a wide variety of material systems. He holds engineering degrees in MSE, ME, and AERO, and has industrial based post-doc experience at General Electric and AT&T Bell Labs.

Weekly Meetings: During the winter 2025 semester, the PPG team will meet on Thursdays 3 – 5pm on North Campus.

Work Location: Most of the work will take place on campus in Ann Arbor, with opportunities to visit a PPG facility in Indianapolis to see the product in use and gather feedback on designs. MDP will provide transportation.

Course Substitutions: CE MDE, ChE Elective, EE MDE, CoE Honors, MECHENG 450, MECHENG 490, SI Elective/Cognate

Citizenship Requirements: This project is open to all students. Note: International students on an F-1 visa will be required to declare part time CPT during Winter 2025 and Fall 2025 terms.

IP/NDA: Students will sign IP/NDA agreements that are unique to PPG.

Summer Project Activities: No summer activity will take place on the project.

Learn more about the expectations for this type of MDP project