The MiTek® Automation Technical Development organization is responsible for creating new and improving existing tools that support factory-based component manufacturing for single and multi-family construction. Students on this team will aim to develop a proof-of-concept automated inspection system to ensure that truss components meet all quality inspection criteria.

Abstract:

MiTek® is a global company focused on providing integrated software, services, engineered products, and automated solutions for the building industry worldwide. Innovating and expanding into aspects of global building, MiTek® empowers customers to improve the way they design, make, and build.

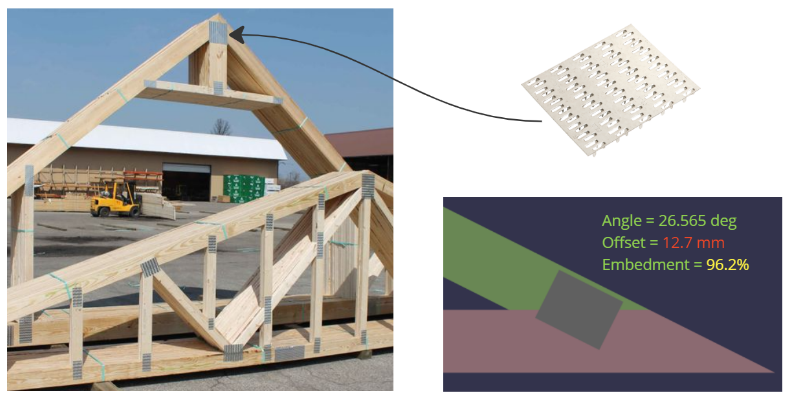

MItek manufacture wooden roof and floor trusses in factories remote from construction sites. Assembly of wooden roof and floor trusses utilize connector gang-nail plates to secure all joints between component members. These joints are often structural, therefore, strict adherence to truss specifications is critical. The connector plates must be placed in the correction locations, with the correct orientation, and be firmly anchored to all wooden supports. The wooden parts must be connected at the correct angles, with no gaps. The industry currently relies on very manual, error-prone inspections to confirm the truss assembly matches design and tolerance expectations.

MiTek® will partner with students to establish system requirements, and design and develop an R&D prototype for continued development into a truss joint inspection product. The students’ machine vision system will collect joint images, analyze them, and report on all quality parameters. The desired programming language for this system is C#.

Impact:

This system will be central in the development of a truss joint inspection product, leading to more repeatable and higher quality manufactured truss components.

Scope:

Minimum Viable Product Deliverable (Minimum level of success)

- Develop an understanding of the current production and quality inspection process at MiTek

- Literature review of existing inspection methods, relevant vision technologies, patents, etc.

- Establish requirements and generate prioritized list of quality attributes

- Demonstrate a rough prototype of vision system able to capture data, evaluate many of the quality attributes with a pass/fail decision, report and store results. Collect feedback on the initial system from stakeholders

- Demonstrate a rough prototype of the mechanical system (equipment mounts, lighting source, environmental protection, etc.)

Expected Final Deliverable (Expected level of success)

- Implement revisions from first prototype. Incorporate detection for additional quality attributes. Integrate and assemble an updated system

- Validate the requirements and document detection accuracy levels for each quality attribute

Stretch Goal Opportunities: (High level of success)

- Validate the system on a wider range of use cases (e.g., low light, dusty, additional truss designs, etc.)

- Use of machine learning/AI to make pass/fail determination of truss joints

Computer Vision (3-4 Students)

Specific Skills: Implementation of computer and machine vision algorithms. Integration of camera and data collection system. General coding.

EECS 281 (or equivalent) is required.

Experience with or willingness to learn C#

Likely Majors: CS, ROB, CE, EE

Mechanical Design (2-3 Students)

Specific Skills: Mechanical design, tool development, testing and validation. Solid understanding of structural analysis.

Knowledge of or willingness to learn about manufacturing quality statistics

Likely Majors: ME, CEE, ISD-MFG

Additional Desired Skills/Knowledge/Experience

- MiTek is a construction technology leader on a mission to advance the adoption of offsite construction. We are a robotics company, and we are interested in people who are interested in robotics, and particularly industrial robotics

- Demonstrated success in team-based project work

- Experience utilizing and/or designing vision systems for CV/MV

- Prior construction experience a plus

- Experience with manufacturing quality assurance

Sponsor Mentor

Scott Kauth

Product Manager, Global Automation Marketing

Scott Kauth has primary responsibility in forming the strategy for development and deployment of new automation solutions for the offsite component manufacturing industry. To ensure product marketability, Scott provides industry insight and represents the voice of the customer. Prior to his role in Marketing, Scott held roles in Manufacturing and Operations management. Scott has a BS in Engineering Mechanics from the University of Illinois Urbana-Champaign and a ME in Mechanical Engineering from the University of Cincinnati. Scott lives with his wife and 2 kids in St. Louis, MO.

Sponsor Mentor

Tyler Lee

Director of Engineering, New Solution Development (NSD)

With over 15 years of experience, Tyler has led various teams to a multitude of solutions ranging, from component level robotic material handling & test automation to large scale factory automation systems. He has also led highly technical objectives as Chief Engineer for numerous high-profile, mission-critical development programs, as well as serving as lead systems engineer & technical liaison for high-complexity system integration activities. Tyler has a BS in Electrical Engineering from Texas Tech University & lives with his wife and 2 kids in Dallas, TX.

Sponsor Mentor

Sean Hirka

Vice President, Global Automation Technology

Sean Hirka strategically leads the global development of innovative offsite manufacturing machine technology solutions for MiTek, Inc – a Berkshire Hathaway Company. He has over 25 years of experience developing and launching products and technologies all over the world. Prior to joining MiTek, he held leadership roles for Dayton Superior, Inc, CBTS, Honeywell, and Dematic. Sean has a BS in Mechanical Engineering from the University of Dayton, and an MBA from Xavier University. Sean and his wife have two grown children, and live in Cincinnati, OH.

Faculty Mentor

Kayvan Najarian, Ph.D.

The focus of Dr. Najarian’s research is on the design of signal/image processing and machine learning methods to create computer-assisted clinical decision support systems that improve patient care and reduce the costs of healthcare. Dr. Najarian’s lab also designs sensors to collect and analyze physiological signals and images, focusing on creating decision support systems to manage traumatic brain injuries, traumatic pelvic/abdominal injuries and hypovolemia. He serves as the Editor-in-Chief of Biomedical Engineering and Computational Biology and the Associate Editor of two other journals in the field of biomedical informatics.

Weekly Meetings: During the winter 2024 semester, the MiTek team will meet on North Campus on Tuesdays from 3:00 – 5:00 PM.

Work Location: Most of the work will take place on campus in Ann Arbor.

Course Substitutions: CE MDE, ChE Elective, CS Capstone/MDE, DS Capstone, EE MDE, CoE Honors, IOE Senior Design, ROB 490, ROB 590, SI Elective/Cognate

Citizenship Requirements: This project is open to all students. Note: International students on an F-1 visa will be required to declare part-time CPT during Winter 2024 and Fall 2024 terms.

IP/NDA: Students will sign standard University of Michigan IP/NDA documents.

Summer Project Activities: Students will be guaranteed an interview for a 2024 summer internship with MiTek in the St. Louis, Missouri area. The interviews will take place before the end of March of 2024. Note: You must have the right work in the U.S.A indefinitely, without sponsorship, to participate in the summer internship program.

Learn more about the expectations for this type of MDP project