The impact to critical electrical connectivity of automotive wire harnesses after thermal exposure is currently evaluated with costly and time-consuming physical testing. The students on the Lear team will research, develop, and design a virtual simulation for the wire and terminal connection to determine its pull strength performance and its resulting circuit resistance delta readings prior and after undergoing high temperature degradation cycles.

Abstract:

With over 100 years of experience, Lear has earned a legacy of operational excellence while building its future on innovation, and is a global technology leader in the automotive seating industry. Innovations in automotive seating such as airbags, heat and ventilation, and massage require increased electrification. This is driving increased complexity in the wire harnessing that powers these functions. In wire harness design, the principal way to achieve electrical interconnection is by the use of two wires with ends terminated with terminals. The desired grip of such a terminal is achieved via an anvil and hammer impaction compression and the terminal is secured in a housing referred to as a connector.

The electrical function of the harness depends on a solid connection at each terminal. The retention force of the wires in the clips is a critical requirement. This force and the associated electrical resistance needs must be accurate not only in ambient conditions, but after significant thermal exposure as well. Currently, evaluation requires long lead physical testing requiring thermal soaks up to a week or longer. This testing protocol is both costly and time consuming, driving up development time and impacting sourcing and design changes.

Students on the Lear team will research, develop, and design a virtual simulation process for the wire and terminal connection to determine its pull strength performance and its resulting circuit resistance delta readings prior and after undergoing high temperature degradation cycles.

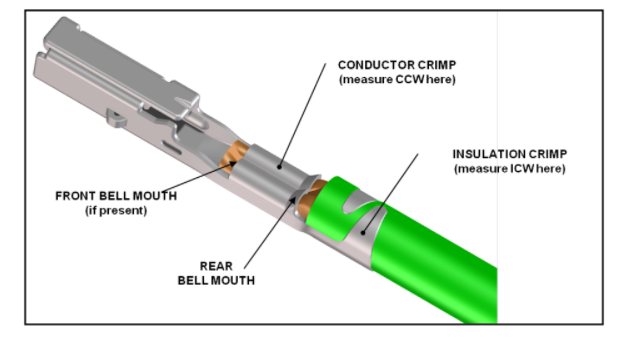

Parts of a Crimp (Isometric View) (Reference image from SAE/USCAR-21 Revision 4)

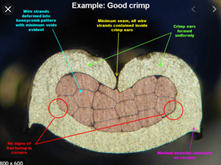

Cross section of Crimped Wire in Terminal

Full Project Details

General Multi-Physics Model Development (2-3 students)

Specific Skills: 1D simulation model development. Multi-physics model Development.

Likely Majors: ChE, MSE, MECHENG, Physics, Chemistry, Math, Any with model development skills

Advanced Multi-Physics Model Development (1-2 students)

Specific Skills: 1D and 3D simulation model development. Multi-physics model Development. A combination of FEA Modeling Techniques. Experience with LS-DYNA a plus.

Likely Majors: ChE, MSE, MECHENG, Physics, Chemistry, Math, Any with model development skills

Thermal Modeling (1-2 students)

Specific Skills: Advanced thermal/materials modeling, including conduction heat transfer.

Likely Majors: ChE, MSE, MECHENG

Finite Element Analysis (1-2 students)

Specific Skills: Composite structures analysis (static stress, cyclic fatigue, and thermal). Minimum completion of MECHENG 305 Introduction to Finite Elements in Mechanical Engineering. Desired completion of MECHENG 505 Finite Element Methods in Mechanical Engineering. Experience with Hyperworks is a plus.

Likely Majors: MECHENG, AERO, NAVARCH, CEE

Sponsor Mentor

Butch Bond

Butch has been a Lear employee for 27 years and is currently the Engineering Manager in the Core Wiring Group that focuses on People, Tools and Process as well as Innovation and advanced product development. Throughout his career, he has held various engineering positions to support worldwide vehicle launches for electrical distribution systems. He is a graduate of Wayne State University with a Bachelor’s Degree in Electrical Engineering Technology.

Sponsor Mentor

Wissam Dhaini

Wissam joined Lear in 1998 and has a Master’s Degree in Mechanical Engineering from the Technical University of Berlin. He is the FEA Senior Manager: Monitoring and training the LEAR FEA team in Germany, Philippines, China and Japan. Wissam’s expertise is in linear and nonlinear crash simulation (LS-DYNA, RADIOSS, OPTISTRUCT).

Faculty Mentor

Johannes W. Schwank

James and Judith Street Professor of Chemical Engineering

Professor Johannes Schwank has taught the capstone design course in Chemical Engineering for many years and has specific expertise in fuel storage technologies. He has developed and taught short courses on fuel cell technology for NASA, and the US Army (TARDEC), that focused on the challenge of hydrogen storage. He testified before a US Congressional Subcommittee on the “Hydrogen Economy”. He has served as director of the University of Michigan Energy Institute and as director of the University of Michigan Center for Materials Characterization. Dr. Schwank is currently the Faculty Co-Director of the Multidisciplinary Design Program.

Course Substitutions: Honors, ChE Elective, CE MDE, EE MDE, IOE Grad Cognate, MECHENG 490, MECHENG 590, SI Elective, SI Grad Cognate

Citizenship Requirements: This project is open to all students.

IP/NDA: Students will sign standard University of Michigan IP/NDA documents.

In Person/Remote Participation Options: Work will take place on campus with occasional visits to the Lear office in Southfield, MI, to hold meetings, leverage design resources, and give presentations, as safety protocols allow. (MDP will provide transportation.)

Students who are approved to attend classes remotely for Winter (and Fall if necessary) 2022 may participate on this project.

Internship/Summer Project Activities: No summer activity will take place on the project.