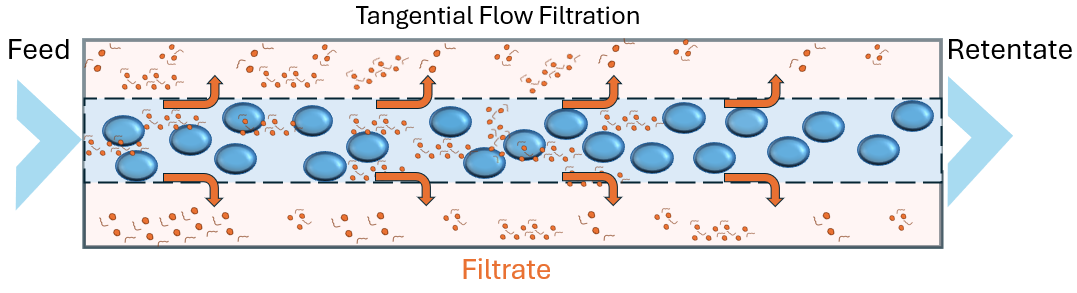

Tangential flow filtration (TFF) membranes are used for purifying proteins and other biological molecules that are grown in cell cultures. With increased demand for faster purification Donaldson is searching for ways to prevent membrane “fouling” (i.e., clogging) which degrades the performance of the membrane. Students on the Donaldson team will characterize mechanisms for fouling during crossflow filtration, and investigate solutions to mitigate the issue.

Abstract:

Donaldson is a global leader in the filtration industry, who prides themselves on their innovative technologies and solutions. One of their many products are tangential flow filtration (TFF) membranes for purifying complex biological solutions. With the rapid development of new pharmaceutical materials such as MRNA vaccines, plasmid DNA and viral vectors, the methods and materials for bio processing filtration that were developed 30 years ago need to be updated. These new methods for growing biologicals are leading to an increased desire for highly efficient purification and concentration strategies. A significant current challenge is membrane fouling; that is, the reversible or irreversible deposition of solutes on the surface of the membrane, or inside the pores of the membrane, during separation processes. As fouling occurs, separations become inefficient, requiring filters to be replaced. This causes delays and potential losses of the valuable pharmaceuticals, vaccines, MRNA, etc.

The student team will characterize the causes of fouling, propose and test potential mitigation strategies by investigating a common separating cell debris from protein products. Students might characterize fouling using a variety of approaches such as those listed below, or develop their own approach.

- monitoring process variables, like pressure drop across the membrane.

- time lapsed visual inspection of membranes.

- investigating surface physical chemistry, surface energy, pore size and interactions between the membrane, protein molecules, and the solvent reclamation

Students might improve membrane performance by implementing additional surface treatments to membranes, adjusting operating conditions, implementing cleaning processes, or innovative solutions proposed by the students. Ideally, students will be able to summarize their learning into heuristics that will provide insight into their learning.

Impact:

Improving TFF membrane performance will accelerate cutting edge scientific development for scientists and engineers, as well as creating a competitive advantage for Donaldson. Significant membrane improvements will eventually enable cheaper pharmaceuticals, allowing more life changing drugs to come to market.

Scope:

Minimum Viable Product Deliverable (Minimum level of success)

- Complete literature/background review of TFF microfiltration membrane structure and fouling mechanisms, focusing on cell harvest clarification, protein separation, and DNA separation as priority use cases. Include academic literature, best practices, patents, and knowledge from the sponsoring organization.

- Brainstorm multiple approaches for preventing fouling based on the knowledge gained in the literature review. Propose a range of potential fouling mechanisms.

- Working with the mentors, prioritize a research plan.

- Set up and learn to run testing equipment (flat sheet filter holder, circulation plumps, pressure sensors, tubing, etc.

- Complete phase one of mechanism investigations; develop working theories for fouling.

Expected Final Deliverable (Expected level of success)

- Refine the phase one deliverables, analyze membrane fouling in a laboratory setting.

- Determine key metrics for understanding in-process fouling of membrane

- Evaluate each through literature and preliminary lab evaluation, prioritize mechanisms for further investigation, and select one for further analysis with input from the mentor team

- Design and implement at least one mitigation strategy

Stretch Goal Opportunities: (High level of success)

- Develop a model for optimizing process parameters to reduce fouling with maximized throughput

- Model and determine ideal membrane characteristics to reduce fouling for specific biofluids

- Build a Digital twin model of the clarification filtration process

MEBelow are the skills needed for this project. Students with the following relevant skills and interest, regardless of major, are encouraged to apply! This is a team based multidisciplinary project. Students on the team are not expected to have experience in all areas, but should be willing to learn and will be asked to perform a breadth of tasks throughout the two semester project.

Separation Processes (2-3 Students)

Specific Skills: Theory and practice of separations, particularly membrane separation processes and measurement of filtrates

Completion of either ChE 343 or BME 331 would be a plus.

Likely Majors: ChE, BME, MSE

Materials Chemistry, and Biomaterials (2-3 Students)

Specific Skills: Materials surface chemistry applied to the interaction of biomaterials and biologic molecules with membranes (e.g., MRNA vaccines, plasmid DNA and viral vectors)

Completion of either BME231 or MSE410 would be a plus.

Likely Majors: MSE, BME, ChE, Chemistry

Mechanical Design (1-2 Students)

Specific Skills: Design and develop research equipment.

Likely Majors: ME

Additional Desired Skills/Knowledge/Experience

If you have any of these characteristics, highlight them on your Experience and Interest Form and talk about them in your (optional) one way video interview.

- Interest in the development and processing of biological and pharmaceutical material.

- Design of Experiments and basic statistical analysis.

- If you have experience in any of the following, we’d like to hear about it:

- Broad-based engineering experience (any major) that will support creative solutions and positive teamwork.

- Practical research and equipment skills.

- Hands-on mechanical prototyping skills.

- Solid data analytic and experimental design skills.

- Fermentation and cell culture processes.

- Cell Biology

- Biomolecule (proteins/DNA/lipids) make up and characterization techniques.

- Interest in learning about downstream processing of biopharmaceuticals.

- Practical lab experience with any of the following (or related) reverse osmosis, filtration, or membranes.

- Experience (or interest in building your skills) in modeling and simulating biological separation processes.

Sponsor Mentor

Karsten Poulsen

Karsten is a Senior Product Development Engineer, working on projects related to the purification and separation of biomolecules. With a background in materials science and chemistry, he holds a PhD from Duke University, where he studied (and predicted) nanoparticle-protein interactions. Outside of work, Karsten enjoys a wide range of hobbies, including 3D printing, DIY house projects, and mountain biking.

David Olson

David is a Principal Research and Development Scientist in the Water Technology & Solutions industry with 15 years of experience in the field of Reverse Osmosis, Nanofiltration, Ultrafiltration, and Microfiltration Membrane development, as well as Spiral wound element design, and Depth & Pleated cartridge filter development. David has studied chemistry, math and polymer chemistry, and holds a PhD in Polymer Chemistry from the University of North Carolina at Chapel Hill.

Xiaobin Wang

Xiaobin is a Principal Model Data Scientist, leading digital innovation activity and working on data science and machine learning projects. He obtained a PhD in Physics from University of California San Diego. Xiaobin has published over 100 papers, is a book author, and holds over 80 patents.

Executive Mentor

Michael Wynblat

Chief Technology Officer of Donaldson

As the CTO of Donaldson, Michael is an Innovation and Technology Executive with extensive experience driving and leading innovation and technology activities in premier companies. A pioneer of “open innovation”, with deep experience in integrated technology-and-business innovation, helping more than 50 technology-based innovations come to market. Michael has a BSE in Computer Science from the University of Michigan, and a PhD in Computer Science from Stony Brook University.

Faculty Mentor

Rohini Bala Chandran

Rohini Bala Chandran is an Assistant Professor in the Department of Mechanical Engineering at the University of Michigan and is the PI in the Transport and Reaction Engineering for Sustainable Energy (TREE) Lab. She was a postdoctoral researcher at Lawrence Berkeley National Laboratory between 2015–2017 in the Energy Storage & Distributed Resources division. Dr. Bala Chandran is a recipient of several awards including the Bergles-Rohsenow Young Investigator Award in Heat Transfer (2023), the NSF CAREER award (2022), the Doctoral New Investigator (DNI) award from the American Chemical Society Petroleum Research Fund, ACS-PRF (2021), and a Doctoral Dissertation Fellowship at the University of Minnesota (2014–2015).

Weekly Meetings: During the winter 2025 semester, the Donaldson team will meet on Fridays 8:30 – 10:30am in FXB 1032.

Work Location: Most of the work will take place on campus in Ann Arbor in various locations.

Course Substitions: CE MDE, ChE Elective, EE MDE, CoE Honors, MECHENG 490, SI Elective/Cognate

Citizenship Requirements: This project is open to all students. Note: International students on an F-1 visa will be required to declare part time CPT during Winter 2025 and Fall 2025 terms.

IP/NDA: Students will sign IP/NDA documents that are unique to Donaldson.

Summer Project Activities: Donaldson will guarantee summer 2025 internship interviews in February 2025 to all interested undergraduate students on the team with eligibility to work in the US indefinitely without sponsorship. Note:

-

- Internships are in person in Bloomington, MN.

- Relocation compensation is not available.

- Graduate students are not eligible for internships.

Learn more about the expectations for this type of MDP project